Walls and Excitement Are Rising at Etzel Sugar Grove Farm

![]()

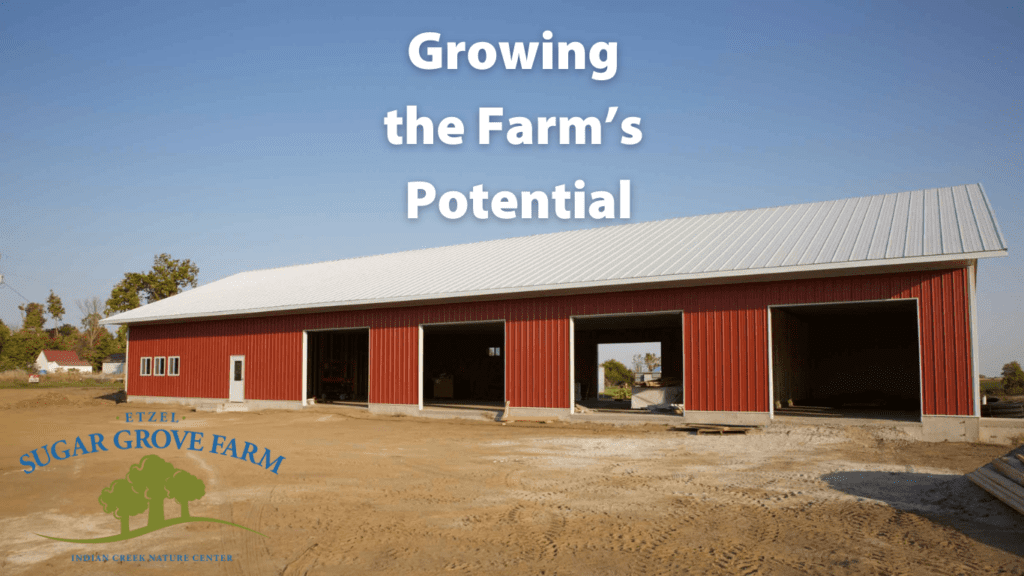

![]() On a warm and sunny afternoon this September, contractor Ron Mormann lifted a wall section into place for the Nature Center’s new 6-bay workshop at Etzel Sugar Grove Farm.

On a warm and sunny afternoon this September, contractor Ron Mormann lifted a wall section into place for the Nature Center’s new 6-bay workshop at Etzel Sugar Grove Farm.

Beyond the partially constructed workshop stood an organic farm ready for expansion.

With the addition of the new workshop, Etzel Sugar Grove Farm, which has been certified organic since 2021, will have the infrastructure needed to provide farmers across the state with an alternative to conventional agricultural practices that often rely on pesticides and fertilizers to keep yields high.

By creating a model farm built on an agricultural system that is both environmentally sustainable and economically self-sufficient, Indian Creek Nature Center is aiming to lead Iowa to a more sustainable future.

In the long run, the new workshop will make operations at Etzel Sugar Grove Farm more efficient and help us meet safety standards.

New Workshop’s Impact on the Farm

![]() The workshop will transform many aspects of the farming operation at Etzel Sugar Grove Farm in ways that will bring the farm closer to being both environmentally and economically sustainable.

The workshop will transform many aspects of the farming operation at Etzel Sugar Grove Farm in ways that will bring the farm closer to being both environmentally and economically sustainable.

Equipment storage out of the elements is important. If you have visited the farm recently, you’ll notice the tractor and a host of tractor implements lined up in the yard, being weed-wacked around or moved periodically for mowing. The contact with the soil and the rain speeds up rust and, with the heavier ones, means digging them out when you go to use them as they settle into the soft earth. An indoor place to store farm equipment and perform maintenance, like routine oil changes and mower blade sharpening, will be deeply appreciated and extend the lifespan of our equipment.

Seasonally, an on-site portable toilet and hand-washing unit has provided basic hygiene for staff, volunteers, and visitors to the farm, but is limited to warm months only. Indoor plumbing at the new workshop will allow us to provide toilets, a safety shower and eye-wash station, and a place to wash eggs and process produce. This makes the farm safer and more accessible, and boosts food production.

Also, having a temperature-controlled facility with ample space for food and equipment storage will have lots of downstream benefits. Right now, we lack the capacity to store anything that needs to be climate controlled.

From a facility management perspective, paints and glues need to be kept from freezing, and equipment, including the chainsaws and snowplow, start better in winter when they aren’t sitting at below-zero temperatures. While the machine storage part of the maintenance building won’t be heated, it will be insulated.

From a food processing and storage perspective, both produce and eggs need to be processed and kept in climate controlled, cleanable spaces.

The new farm workshop will enable us to scale up organic food operations, increase the longevity and utility of equipment, and improve basic hygiene and safety standards.

Building for the Future

Ground was broken on a new workshop this past spring. Using structural insulated panels (SIPs) in the construction process creates a solid thermal barrier against the elements and makes for an efficient installation.

Each panel is prefabricated in Graettinger, Iowa by EPS Buildings. A panel consists of a block of styrofoam cemented in between two pieces of oriented strand board (OSB). A groove cut into each panel allows them to be wedged together, forming tight seams.

Since those wall sections began going up on that sunny afternoon in September, construction crews have added siding, windows and a roof. With construction expected to be completed before the end of the year, we can’t wait to see how the new workshop will transform Etzel Sugar Grove Farm into a model of sustainable agriculture in the growing seasons to come.